Using an RFID Reader to Increase Profitability

Inventory management is important for every type of business, but none more so than the food distribution industry. While misplaced inventory will always result in lost time, misplaced, mishandled or misdirected food packages result in a quantifiable monetary loss. Having the right asset management process in place is the one of the most efficient ways to avoid these costly losses. Through the use of a wireless barcode scanner or RFID reader system, food distribution companies and their retail counterparts can help ensure profitability by taking advantage of the following applications:

Implementing a loading procedure

In the food distribution industry everything starts with loading because a truck that has an improper load will take longer to receive. It’s important that the items are loaded in order, but also that the barcodes are visible for the receivers. Creating a sophisticated loading procedure depends heavily on the accuracy and speed at which the warehouse can prepare goods. By utilizing a barcode scanner and RFID system, the warehouse can ensure the right goods are in the right areas.

Implementing a receiving procedure

The right receiving process can greatly reduce the amount of time and labor needed to unload each shipment. Using a wireless barcode can help receivers identify specific products and an RFID reader can enter this information immediately into an inventory database.

Implementing a stocking procedure

Maintaining inventory is costly at any rate, but in the retail food industry it is usually not even an option. It’s crucial for retailers to stock the right amount of product and receive new shipments on a more frequent basis. The key to a good stocking procedure is inventory control; being able to understand what you have and what you need very quickly. The only problem is that tracking assets can be difficult in a distribution environment where inventory is in constant motion. As a result, each item needs to tracking at every step along the way.

In terms of the retailer, this is done using an RFID reader system during receiving and a wireless barcode scanner system at the point of sale. When this data is input into an enterprise mobile application it can give retailers an accurate inventory level. This can be sent off to the distribution centers almost immediately.

Accuracy and speed are undeniably two of the most important factors to achieving profitability in the food distribution industry. Without the right procedures in place a small error can add up and become quite time consuming and costly. Utilizing a wireless barcode scanner system and/or RFID system distributors and retailers implement save time, reduce errors and save money.

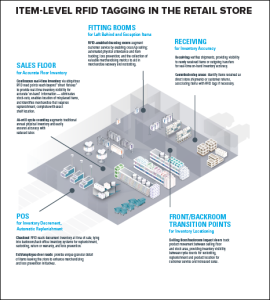

Learn more about item-level RFID tagging in retail: click here

Watch a video on ShipTrack barcode scanning – click here